2mm wire to board connectors is widely used in many fields, like consumer, Data and communication application. JST PH 2mm connector & Molex MicroBlade connector are popular. Yeonho 2mm connector with lock device, JAE IL-S connector is widely used in the battery.

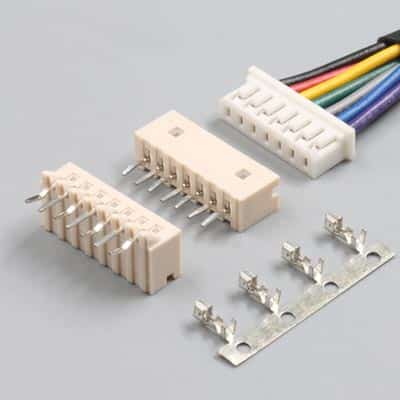

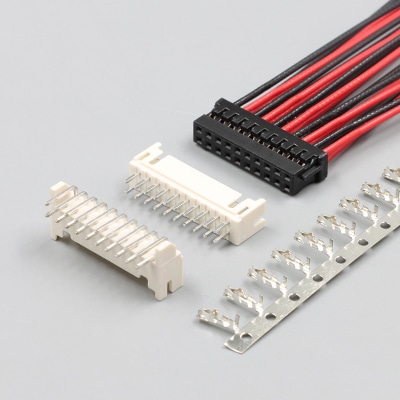

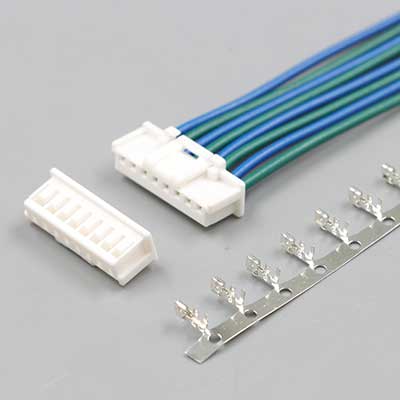

SCT2001 Series

Cross: JST PH Connector

Pitch: 2.0mm

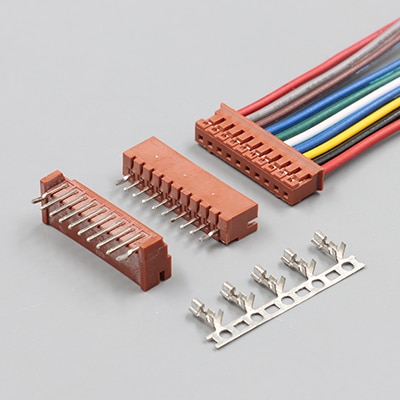

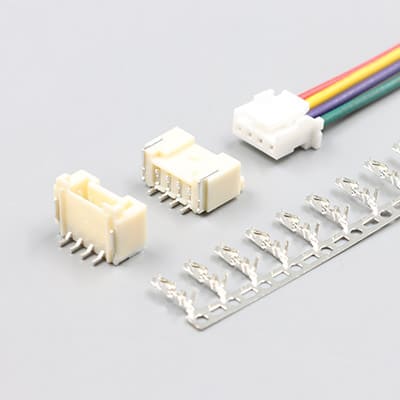

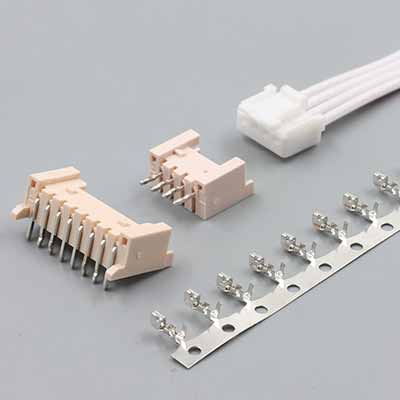

SCT2002 Series

Cross: Molex MicroBlade Connector

Pitch: 2.0mm

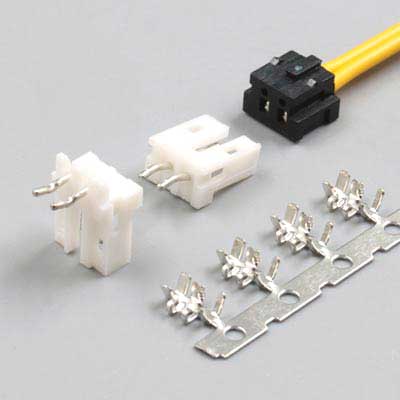

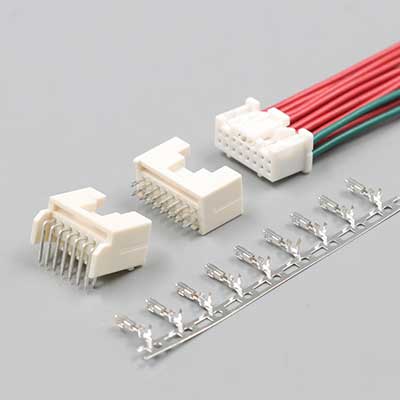

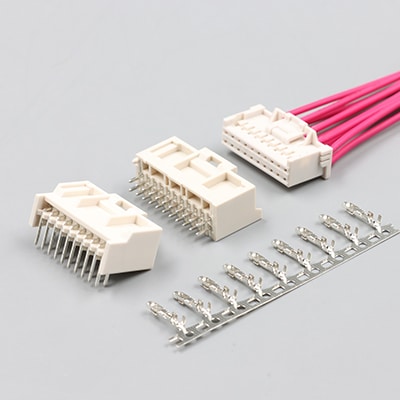

SCT2004 Series

Cross: JST PHD Connector

Pitch: 2.0mm

SCT2005 Series

Cross: JAE IL-S Connector

Pitch: 2.0mm

SCT2006 Series

Cross: Yeonho 2.0 Connector

Pitch: 2.0mm

SCT2007 Series

Cross: AMP2.0 Connector

Pitch: 2.0mm

SCT2009 Series

Cross: Yeonho SMAW200-NNC Connector

Pitch: 2.0mm

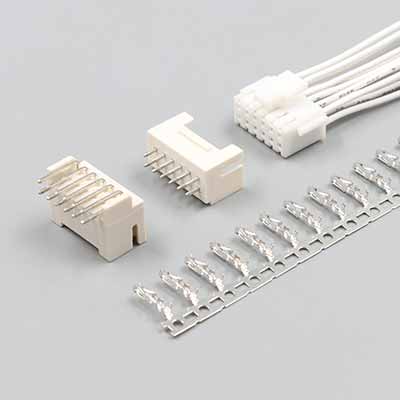

SCT2011 Series

Cross: Hirose DF11 Connector

Pitch: 2.0mm

SCT2012 Series

Cross: JST PA Connector

Pitch: 2.0mm

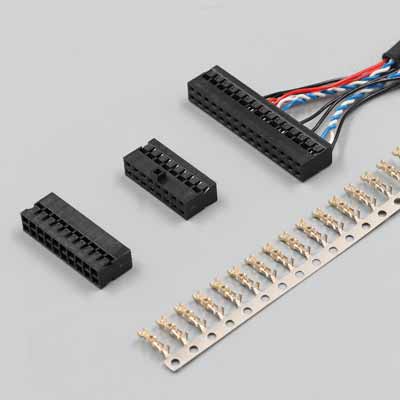

SCT2015 Series

Cross: Dupont2.0 Connector

Pitch: 2.0mm

SCT2020 Series

Cross: JST PUD Connector

Pitch: 2.0mm

SCT2023 Series

Cross: Molex CLIK-Mate Connector

Pitch: 2.0mm

SCT2025 Series

Cross: Molex iGrid Connector

Pitch: 2.0mm

SCT2026 Series

Cross: Molex Sherlock Connector

Pitch: 2.0mm

SCT2027 Series

Cross: Molex Pico-Lock Connector

Pitch: 2.0mm

SCT2028 Series

Cross: Molex DuraClik Connector

Pitch: 2.0mm

SCT2029 Series

Cross: JST PND Connector

Pitch: 2.0mm

SCT2030 Series

Cross: JST PAD Connector

Pitch: 2.0mm

2.0 mm (0.079”) Pitch Connector

What is a 2.0 mm Pitch Connector

The compact 2.0 Pitch Scondar connectors is based on a 0.079” pitch and is rated for 250VAC at up to an industry-leading 3.0A. With a 30 to 22 AWG wire size, and up to 40-positions, 2.0 pitch connector is suited for signal and low power PC board connections when space is at a premium.

All of Scondar’s 2.0 pitch connectors have two levels of mechanical and electrical reliability: A friction latch prevents the plug housing and shrouded header from vibrating apart, while an optional Terminal Position Assurance (TPA) device helps assure terminal seating.

Scondar offers 2.0 pitch connectors 100% compatible with original brand, like JST PH and PHD Connector, Molex MicroBlade, JAE IL-S series, Yeonho, AMP, Hirose and Dupont DF11 connectors.

Molex MicroBlade Connector

MicroBlade is Molex’s leading wire-to-board and wire-to-wire 2.0mm pitch connector system providing design flexibility with multiple header options, ideal for a variety of applications across many industries, such as DVD Players/Recorders and digital cameras. Like PicoBlade, this connector has an overmolded shell feature designed for high density, high speed harness and crowded applications, withstanding higher strain and mechanical stress.

This connector has a top entry and a side entry height of 4.35mm and depth of 9.35mm, delivering 2.0A AC/DC, and is available in 2-15 circuits, accepting a range of 24 AWG to 30 AWG. It has a polarized mating feature that prevents any sort of mis-mating of harness to header.

JST PH Connector

The 2.0 mm JST PH connector series is a low-profile and compact component delivering dependable service in requirements for high density connection to printed circuit boards. It is specifically designed for harsh environments which are frequently subjected to heat and vibration such as in heavy equipment vehicles and batteries.

Delivering up to a current rating of 2.0 A and 250 V, it is applicable for AWG 24-28. It is enclosed in crimp-style lock and a completely polarized configuration which prevents users from inverted insertion. Top entry configuration consumes a minimum of 8 mm x 4.5 mm mounting height and width, respectively; while side entry configuration consumes a minimum of 4.8 mm x 9.6 mm mounting height and width, respectively.

JST PHD Connector

This 2.0mm pitch crimp -style, double-row wire-to-board connector is designed for high density and low-profile connection with a PCB board thickness of up to 1.6mm.

The JST PHD series can deliver a higher current rating than that of the PH series, up to 3.0 A at 250 V. It is applicable for AWG 22-28. Top entry configuration consumes a minimum of 8 mm x 5mm mounting height and width, respectively; while side entry configuration consumes a minimum of 5 mm x 11.8 mm mounting height and width, respectively.

JAE IL-S Connector

IL-S Seriies connectors are low profile connectors with crimp termination socket contacts permitting fast and simple semi-automatic termination. It has a box-type pin header which prevents mismating and a design preventing flux wicking. IL-S is also available in straight, right-angle and bottom through hole types with top entry width of 4.6mm and height of 7.5mm and a side entry width of 9.2mm and height of 4.6mm.

Number of contacts ranges from 2 to 15 delivering a current rating of 3Amps per contact with an operating voltage of 300 VAC, 400VDC for AWG #22 to #28 for a maximum PCB thickness of 1.6mm with a temperature range of -40 deg C to 85 deg C.

Yeonho 2.0 Connector

This low-profile connector with polarized design and crimp-style is SMT compatible, rated at 3.0A AC/DC, 250 volts and can accommodate 24-30 AWG. The contacts are tin-plated phosphor bronze providing reliability in signal transmission. Its components such as the housing and header are molded in a 94V- 0 PBT and is also ideal for rugged electronics devices, sustaining environmental stresses, complying with RoHS standards.

The series has an operating temperature range of -25 C to +85 C including temperature rise when applying an electrical current. It is offered in 2-16 positions. Furthermore, the series is supported with termination tooling.

AMP 2.0 Connector

TE AMP 2.0 pitch connector is offered with either shrouded or unshrouded headers in surface mount and through-hole configurations. This connector is available in single or double row configurations with .025″ square posts and a current rating of 3 amps max per contact.

TE AMP can accommodate a variety of high density packaging applications in right-angle wire-to-board applications. The 2.0mm pitch allows efficient use of the PCB area. Mechanical support of the headers to the PC board is provided by non-protrusive metallic hold downs designed for 1.6mm PCB. Metallic tabs are present on the surfaces for support. This connector is present in 2-16 positions with headers featuring polarization to help prevent misalignment during mating.

Hirose DF11 Series Connector

DF11 is a space-saving, dual row 2mm pitch contact condensing to about 5mm connector width. It can perform the same realization of signals as compared with a conventional single-row contact. This type of series connector is available for insulation displacement and crimping methods. Applicable wires are from AWG #22 to #30 with a surface mounting (SMT) header that is specifically designed to prevent solder peeling through its durable metal fitting.

When using the automatic insulation displacement, the multi-harness can be easily connected, reducing man-hour and eliminating manual labor process. Hirose DF11 can deliver a current rating up to 2.0A at 250V AC/DC.

Dupont 2.0 Connector

Dupont 2.0mm pitch series is low-profile connector available in a single-row or dual-row configuration and designed for wire-to-board cable applications with high-density contact spacing SMT. A friction lock housing enables secure connections. This series delivers a current rating of 2A, 250 VAC/VDC for a maximum PCB thickness of 1.6mm and for wire gauge AWG #24 to AWG #30.

Components of 2.0 mm Pitch Connectors

Housing

The connector housing provides electrical insulation between the contacts and between the contact and the external circuit. Dielectric Withstand Voltage (DWV) usually verifies the voltage rating of the connector.

A well-designed housing holds the connector contacts providing trouble-free mating and unmating. Spacing between the contacts is also fixed by the housing. Creep (electrical tracking distance over surfaces) and clearance (linear “line‐of‐sight” distance) is also maintained by the housing.

The housing is smartly engineered to allow efficient signal and power transmissions and at the same time, provide some level of environmental protection to the electrical contacts.

Scondar manufactures the housing from Nylon 66, which is a material highly used when high mechanical strength, rigidity, stability is needed under varying temperature changes. That is why all Scondar connectors can withstand a wide temperature range from between -25 deg C to 85 deg C.

Furthermore, the housing is molded in UL94V0 natural ivory and is RoHS compliant, which has passed the flammability test for electronics and as such, the connectors produced by Scondar are ideal in rugged electronic devices, sustaining high environmental stresses. Also, the housing may be available with or without protrusions, depending on customer needs and specifications.

Header

The header contact is made up of copper alloy, tin plated over a phosphor bronze material.

Terminal

Scondar’s connector terminals are made of tin-plated, phosphor bronze. The terminals have a thickness range of 0.12mm-0.15mm depending on the 2.0mm connector type and standard reels are 20,000 pieces per reel.

Tin-Plating

Tin-plating is less costly and generally for applications carrying more than 0.5A, where high cycling is specified.

Phosphor bronze

Phosphor bronze is stronger than brass and has better spring properties that lends itself useful in smaller contacts that can best leverage its mechanical properties. This material is commonly found in small and medium‐pitch signal and moderate‐power connectors.

Quality Assurance of Components

How Scondar makes 100% Reliable and Compatible Connectors

Quality is at the heart of Scondar’s standards where facilities are UL & ISO 9001:2008 certified. Scondar ensures materials and components always meet their needs with UL file number and ISO certification.

Assemblies are 100% tested guaranteeing reliability and compliance, a variety of appropriate tests are applied depending on cable assembly type. Examples are: Short or open circuit, intermittent circuit, mis–wiring. Hi-Pot, static load for strain relief, bending test, crimp pull off force, contact to housing retention force and plastic hardness.

Individual discrete wires are stripped of insulation, crimped and then inserted into female housing to complete the assembly. The completed assembly mates with a male PCB header, which offers options for locking, latching and polarised connectors.

Wiring Harness/Cable Assembly

In many cases, a wire harness or cable assembly is needed to compress masses of wires stretching over a distance. By binding these wires into cable assemblies, these cables can be better secured against the adverse effects of vibrations, abrasions, and moisture.

Scondar’s wires are produced into a non-flexing bundle, for space optimization and safety purposes, where installation time can be decreased and the process of installing electronic circuits in standardized. Their positive locking latch provides only a slight increase in disengagement force of the terminals.

Blind-mating solutions implemented in the connectors allow engagement of the connector system without visual alignment. Scondar connector series has a heavy-duty, shrouded design providing positive polarization to aid in blind mating applications. Scondar meets close adherence to the connector system specifications for blind-mating solutions for a more efficient connecting system and interference capability.

Wire Gauge

For 2.0mm connectors, wire gauges that can be accommodated with the rated current and voltage is between AWG #22-30. The following table represents the specs of these wire gauges.

| AWG | Conductor Diameter in mm | Conductor Cross Section mm2 | Maximum amps for chassis wiring | Maximum amps for power transmission |

| 22 | 0.64516 | 0.327 | 7 | 0.92 |

| 23 | 0.57404 | 0.259 | 4.7 | 0.729 |

| 24 | 0.51054 | 0.205 | 3.5 | 0.577 |

| 25 | 0.45466 | 0.162 | 2.7 | 0.457 |

| 26 | 0.40386 | 0.128 | 2.2 | 0.361 |

| 27 | 0.36068 | 0.102 | 1.7 | 0.288 |

| 28 | 0.32004 | 0.080 | 1.4 | 0.226 |

| 29 | 0.28702 | 0.0647 | 1.2 | 0.182 |

| 30 | 0.254 | 0.0507 | 0.86 | 0.142 |