The 2.0mm (.079”) male Surface Mount Technology (SMT) pin header connector is a versatile and reliable component, designed for various electronic applications. With a range of features that cater to the needs of modern electronic devices, this connector stands out for its performance, adaptability, and compliance with industry standards. Here, we delve into its features, applications, and the advantages it offers.

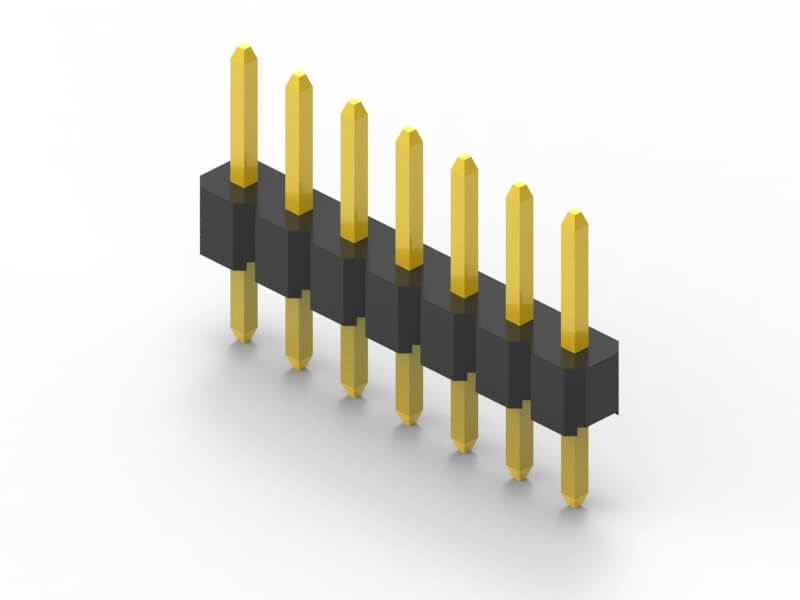

PH200H200SMT-1xxL820GA1301A

Row: Single

Circuits: 2 – 40 pins

Angle: Vertical

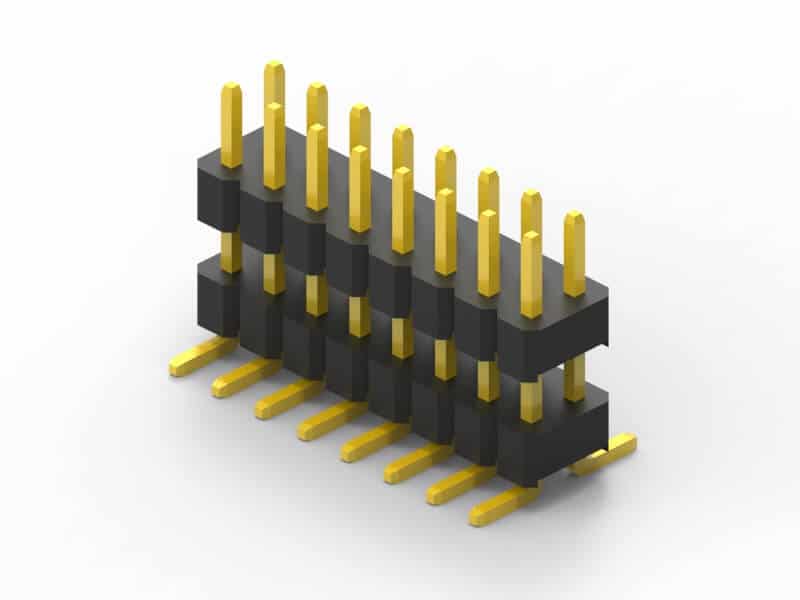

PH200H200SMT-1xxL820GA1301A

Row: Dual

Circuits: 2 – 80 pins

Angle: Vertical

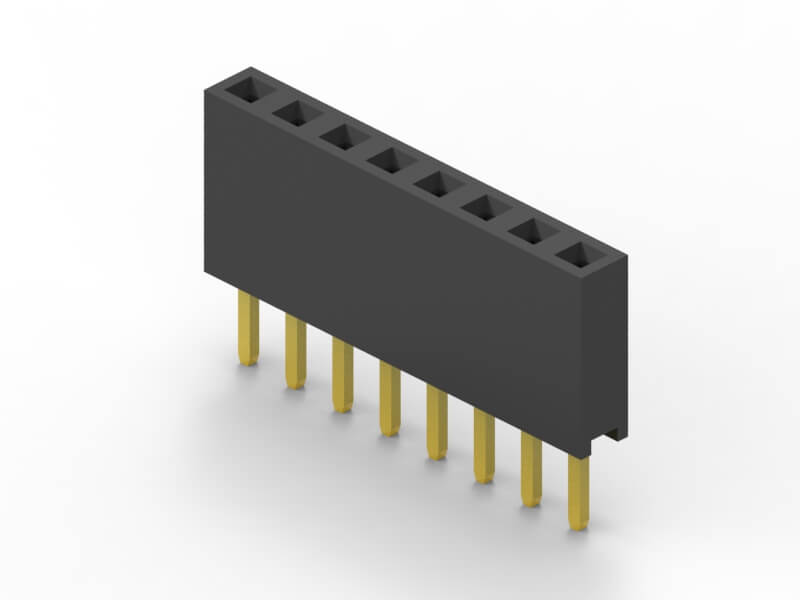

PH200DH200SMT-2xxGA1301

Row: Dual

Circuits: 2 – 80 pins

Angle: Vertical

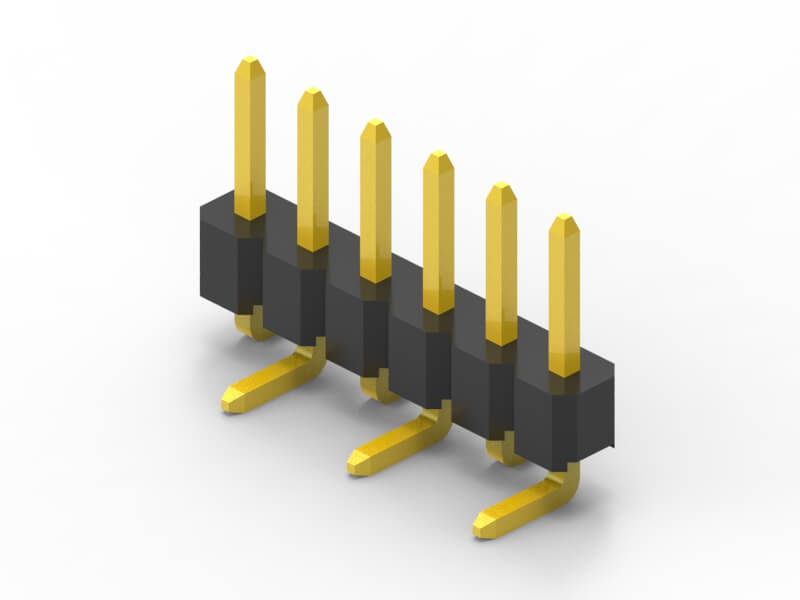

PH200H200RMT-1xxL950GA1301

Row: Single

Circuits: 2 – 40 pins

Angle: Right-Angle

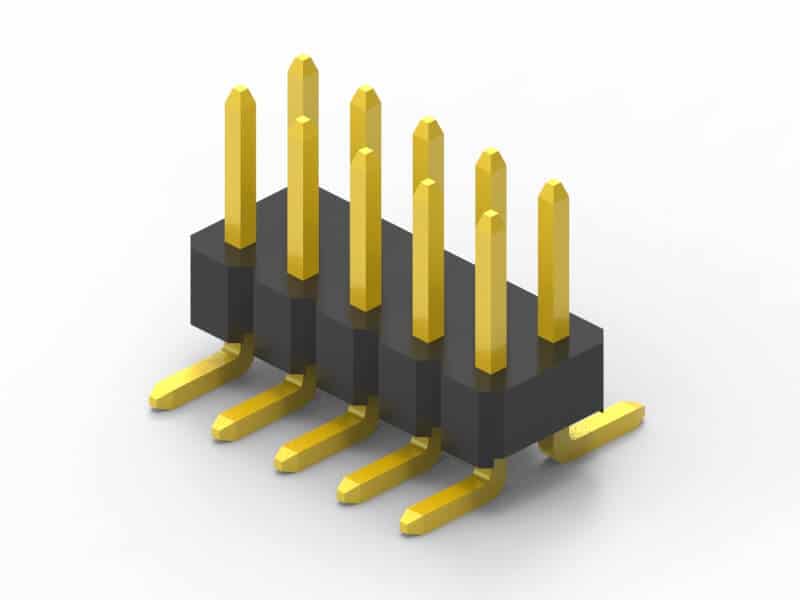

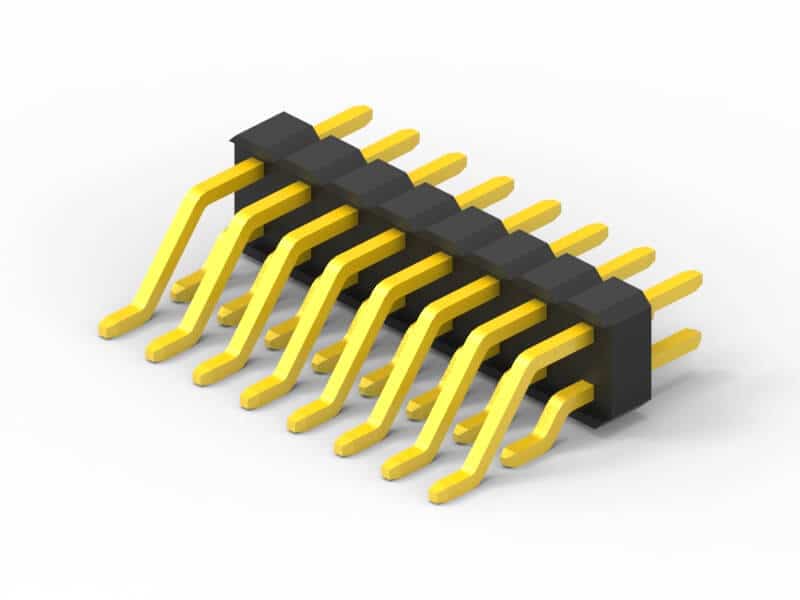

PH200H200RMT-2xxL1350GA1301

Row: Dual

Circuits: 2 – 80 pins

Angle: Right-Angle

| General | Spec. |

|---|---|

| Product Name: | 2.0mm (.079”) male SMD (surface mount) pin header connector |

| Pitch(spacing): | 2.0mm (.079”) inch pitch |

| Gender: | Male |

| Breakaway: | No |

| Number of Contact: | 2 – 40 pins (single row); 4 – 80 pins (dual row) |

| Number of Rows: | Single or dual |

| Orientation: | SMT(surface mount) SMD |

| locating peg | Optional |

| Material: | High Temperature Thermoplastic |

| Contact material: | Brass or Phosphor Bronze |

| Insulator material: | PA6T (Optional:LCP NA6T PA46 PA6T) + UL94V-0 |

| Insulator color: | Black |

| Flammability: | UL94V-0 |

| Contact Plating: | Gold flash over 50μ” nickel or custom |

| Pin lengths: | Standard(refer to drawing) or Customizable |

| PC Tail Length: | Standard(refer to drawing) or Customizable |

| Packaging Type: | Bulk in Tube or Tape&Reel |

| RoHS compliant: | Yes |

Pitch and Configuration:

- Pitch: 2.0mm (.079”) spacing between pins.

- Configurations: Available in single-row with 2 to 40 pins or dual-row with 4 to 80 pins.

- Orientation: Designed for surface mount technology (SMT), ensuring easy integration into PCB designs.

- Breakaway: Non-breakaway design for solid, uninterrupted connections.

Material and Plating:

- Contact Material: Made from brass or phosphor bronze, ensuring excellent conductivity and durability.

- Contact Plating: Gold flash over 50μ” nickel, with custom plating options available, providing superior corrosion resistance and electrical conductivity.

- Insulator Material: Constructed from high-temperature thermoplastic with options including PA6T, LCP NA6T, and PA46, all UL94V-0 rated for flammability resistance.

Customization Options:

- Pin Lengths and PC Tail Length: Standard lengths as per the drawing or customizable to meet specific application requirements.

- Locating Peg: Optional, to aid in precise placement during assembly.

- Packaging: Available in bulk in tube or Tape & Reel packaging, suitable for automated assembly processes.

Compliance:

- RoHS Compliant: Ensures that the connector meets the European Union’s Restriction of Hazardous Substances Directive, making it environmentally friendly and safe for use in various applications.

Consumer Electronics:

- Widely used in devices like smartphones, tablets, and laptops due to its compact size and reliable performance.

- Essential in connecting various modules and components within these devices.

Industrial Equipment:

- Utilized in control systems, automation equipment, and instrumentation where robust and dependable connections are crucial.

- Suitable for harsh environments due to its high-temperature thermoplastic construction and durable contact materials.

Automotive Electronics:

- Integrated into vehicle control units, infotainment systems, and sensor modules.

- High flammability rating (UL94V-0) ensures safety and reliability under demanding automotive conditions.

Medical Devices:

- Used in diagnostic equipment, monitoring systems, and handheld medical devices where precision and reliability are paramount.

- RoHS compliance ensures these connectors meet stringent health and safety standards.

Reliability:

- High-quality materials and robust construction ensure long-term performance and reliability.

- Gold flash over nickel plating provides excellent resistance to oxidation and wear, ensuring consistent electrical connectivity.

Flexibility:

- Customizable pin lengths and PC tail lengths allow for tailored solutions to specific design requirements.

- Optional locating peg ensures accurate placement and alignment during the assembly process.

Ease of Use:

- Surface mount design simplifies the assembly process, making it compatible with modern automated manufacturing techniques.

- Available in Tape & Reel packaging for seamless integration into high-volume production lines.

Safety and Compliance:

- UL94V-0 flammability rating and RoHS compliance guarantee that these connectors meet rigorous safety and environmental standards.

- Suitable for use in applications requiring high safety and reliability standards.

In conclusion, the 2.0mm male SMD pin header connector is an essential component for a wide range of electronic applications. Its robust design, flexibility, and compliance with industry standards make it a preferred choice for engineers and manufacturers seeking reliable and high-performance connectors. Whether used in consumer electronics, industrial equipment, automotive systems, or medical devices, this connector delivers exceptional value and performance.