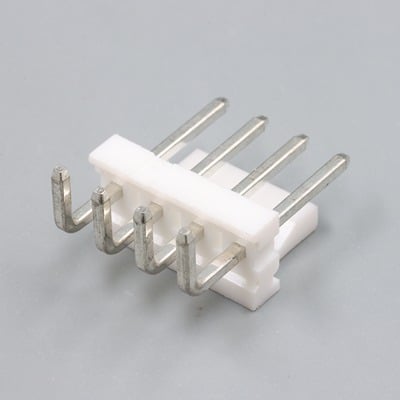

SCT3963 Series

TE MTA-156 IDC connectors are 3.96mm pitch wire-to-board and wire-to-wire connectors designed for fast, reliable, and tool-assisted insulation displacement termination.

Specification

| Series | SCT3963 Series |

|---|---|

| Contact Pitch | 3.96mm |

| No.of Contacts | 2 to 18 positions |

| Current | 7A (AWG #18 to #26) |

| Compatible | Cross AMP(TE) MTA-156 Connector Series |

| Current Rating: | 7A |

| Voltage Rating: | 250V |

| Temperature Range: | -40°C~+105°C |

| Contact Resistance: | 10m Omega Max |

| Insulation Resistance: | 1000M Omega Min |

| Withstanding Voltage: | 1500V AC/minute |

Understanding TE MTA-156 IDC Connectors – 3.96mm Pitch Wire-to-Board Solutions

TE MTA-156 IDC connectors are widely used 3.96mm pitch wire-to-board and wire-to-wire interconnect solutions designed for reliable, fast, and low-cost wiring in both industrial and consumer applications. Leveraging insulation displacement contact (IDC) technology, they allow efficient termination without the need for stripping or soldering, which simplifies assembly and reduces labor costs.

What is an MTA-156 IDC Connector?

An MTA-156 connector is a type of IDC (Insulation Displacement Contact) connector with a 3.96mm (0.156 inch) pitch, commonly used for power and signal transmission in medium-duty electrical systems. These connectors are engineered to accommodate discrete wires directly into the housing using a specialized tool that presses the wire into sharp contact slots, piercing the insulation and forming an electrical connection.

Key Characteristics

Pitch Size: 3.96mm (0.156”)

Termination Method: IDC (no stripping or soldering required)

Wire Gauge Range: Typically supports 18 to 24 AWG

Positions Available: From 2 to 24 positions depending on configuration

Current Rating: Up to 10A (depending on wire size and layout)

Housing Design: Polarized and keyed to prevent mis-mating

Mounting: Wire-to-board or wire-to-wire, horizontal or vertical orientation

Color Options: Often color-coded to indicate wire gauge compatibility

Material: UL94V-0 rated thermoplastic, tin or gold-plated contacts

How IDC Technology Works

IDC connectors eliminate the traditional steps of wire preparation. Instead of stripping the wire and crimping a terminal, the IDC contact is designed to cut through the insulation and make contact with the conductor when the wire is pressed into the slot. This ensures a consistent, gas-tight, and vibration-resistant connection that saves time during mass production or field installation.

Common Applications

MTA-156 compatible connectors are widely adopted in applications where quick and reliable wiring is essential:

HVAC systems

Industrial control panels

Vending and gaming machines

Home appliances

LED lighting

Communication systems

Transport systems

Modular wiring harnesses

They are especially suitable for internal power distribution, signal interconnects, and modular PCBs where moderate current handling and field-terminable connections are needed.

Advantages of Using MTA-156 IDC Connectors

Fast Assembly: No wire stripping or soldering

Reduced Wiring Errors: Pre-keyed housings prevent reverse insertion

Reliable Contact: Gas-tight IDC termination resists shock and vibration

Tool-Assisted Termination: Compatible with manual or semi-automatic tools

Flexible Configurations: Available in multiple pin counts and wire orientations

Cost-Effective: Ideal for both low- and high-volume production

Summary

MTA-156 IDC connectors offer a practical, time-saving solution for 3.96mm pitch interconnect requirements. Their tool-assisted IDC termination, moderate current capacity, and broad application range make them a preferred choice for both OEM and field-installation wiring tasks.

Whether used in industrial systems, consumer electronics, or electrical panels, these connectors help simplify wiring, improve reliability, and streamline production.