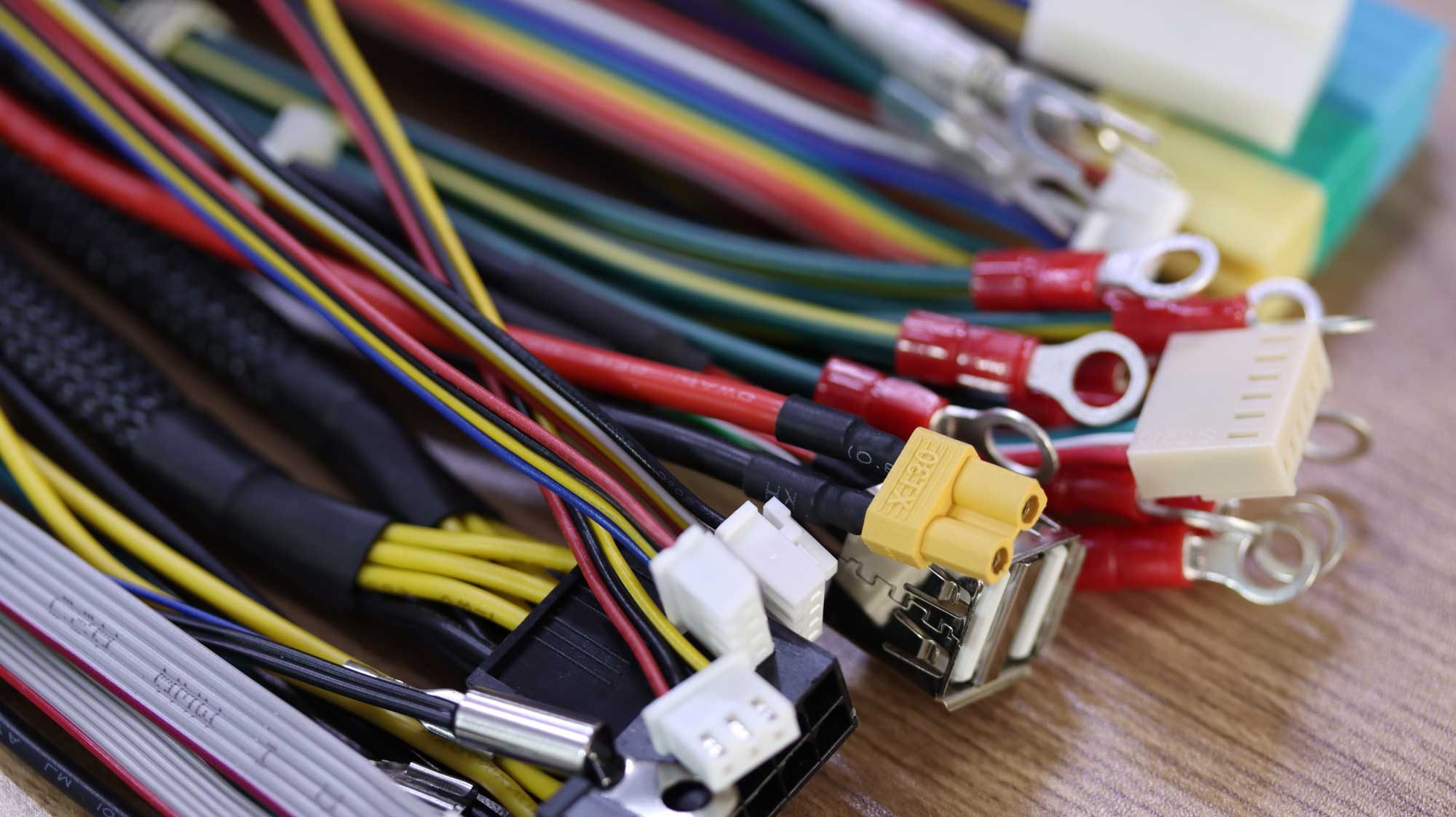

1. What Is a Wire Harness?

A wire harness, also known as a cable harness or wire assembly, is an organized bundle of electrical wires or cables that transmit power and signals within a device or system. These harnesses are essential in applications where space-saving, safety, and reliable connectivity are critical—especially in automotive, industrial, aerospace, medical, and consumer electronics.

2. Wire Harness Manufacturing Process

Wire harness manufacturing involves a series of carefully planned steps to ensure electrical performance, durability, and safety. Here’s a breakdown of the typical production process:

2.1 Wire Cutting

Wires are cut to precise lengths using automatic cutting machines.

Accuracy here ensures consistency in final assembly.

2.2 Stripping

The insulation at the ends is removed (stripped) without damaging the conductor.

Both manual and semi-automatic machines are used depending on volume and precision needs.

2.3 Crimping or Soldering

Terminals or connectors are attached using crimping (mechanical compression) or soldering.

Crimped terminals must pass pull-force and visual inspection tests.

2.4 Connector Assembly

Multiple wires are routed and inserted into plastic connectors or housings according to the wiring layout.

2.5 Harness Layout

Wires are arranged on a harness board or jig to replicate the final design, ensuring correct routing and dimensions.

2.6 Bundling and Protection

Wires are bundled using cable ties, heat shrink tubing, spiral wrap, or PVC sleeves.

Shielding or overmolding may be added for mechanical or electromagnetic protection.

2.7 Testing and Quality Control

Final harnesses undergo continuity testing, high-voltage testing, or visual inspection to ensure functionality and reliability.

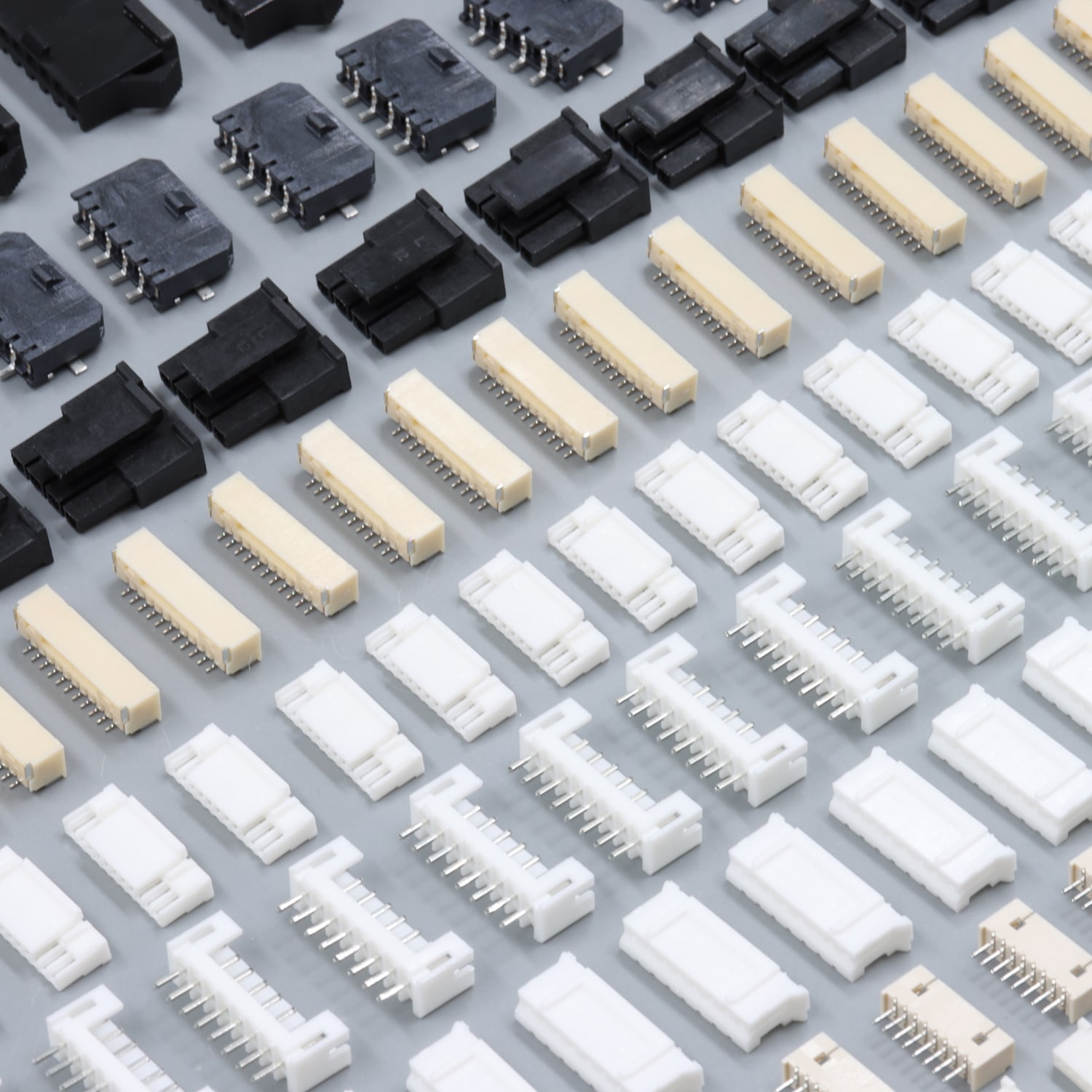

3. Key Materials Used

3. Key Materials Used

Conductors: Copper (tinned, bare, or stranded)

Insulation: PVC, Teflon, XLPE, silicone

Connectors: Molex, JST, TE, Hirose, custom types

Sleeving: Braided sleeving, PET, PVC tubing

Terminals: Ring, spade, blade, or custom crimps

4. Applications of Wire Harnesses

Wire harnesses are used in almost every industry that involves electrical or electronic systems. Common application areas include:

| Industry | Application Examples |

|---|---|

| 🚗 Automotive | Dashboard wiring, engine bay harnesses, lighting |

| 🏭 Industrial Automation | Control panels, servo motor systems |

| ✈ Aerospace | Navigation systems, communication units |

| 🏥 Medical Devices | Diagnostic equipment, patient monitors |

| 💻 Consumer Electronics | Computers, TVs, gaming consoles |

5. Custom Wire Harness Solutions

OEMs and manufacturers often require custom wire harnesses tailored to specific applications, involving:

Unique wire lengths and connector combinations

Specialized materials for heat, chemical, or abrasion resistance

High-current or high-speed signal transmission requirements

Labeling, barcoding, or traceability features

Partnering with an experienced wire harness manufacturer ensures design-for-manufacturing (DFM) support, faster prototyping, and scalable production.

6. Conclusion: Quality in Every Connection

Wire harness manufacturing is more than just bundling wires—it’s about creating reliable, efficient, and long-lasting electrical pathways. Whether you’re designing for a car, a robot, or a server, the quality of your wire harness impacts the performance of your entire system.

Looking for a trusted wire harness manufacturer?

👉 Contact us today to request a quote or discuss a custom solution.