Electrical connectors play a crucial role in ensuring reliable and efficient connections within electronic and electrical systems. They are categorized into six levels based on connection hierarchy, ranging from the chip-to-enclosure or main circuit board level to system-to-system or system-to-peripheral connections. This article discusses the levels of connection, design considerations, and types of connectors commonly used in the industry.

1. Connection Levels

Electrical connections can be divided into six hierarchical levels:

- Chip to enclosure or main circuit board: Permanent connections that ensure the chip’s functionality within the assembly.

- Enclosure to PWB (Printed Wiring Board): Connections that integrate the enclosure with the circuit board.

- Between PWBs: Connecting two or more circuit boards in a single system.

- Between system components: Connections that link individual modules within a system.

- System to input/output (I/O): Facilitating external communication with the system.

- Between systems or system to peripherals: High-durability connections for inter-system communication or connecting peripherals.

2. Design and Selection Considerations

When designing or selecting connectors, two primary factors are critical:

- Separability and Durability

- Level 1 and Level 2: These connections were historically permanent and did not consider separability.

- Level 3: Introduced the concept of separable connections, with durability becoming a secondary concern. For connectors with many terminals, low insertion force (LIF) and zero insertion force (ZIF) designs are key to managing insertion and extraction forces. These designs must also consider terminal durability to meet Level 2 requirements.

- Levels 4 and 5: Require connectors with higher insertion/extraction cycles. These connectors strike a balance between terminal insertion force and durability, even for connectors with dozens or hundreds of terminals.

- Level 6: Focuses on significantly increasing the number of effective terminal insertions/extractions without compromising original insertion force. For example, card connectors connected to peripherals must withstand thousands of cycles, demanding strict control over interface design and material selection, particularly as connectors are miniaturized to improve density.

- Standardization

- Standardization ensures compatibility and interchangeability between various connection types.

- Levels 1 and 2: Emphasize packaging and mounting standards.

- Levels 3 and 4: Involve production and assembly standards to meet connectivity requirements.

- Levels 5 and 6: Focus heavily on interoperability and compatibility across systems.

It is important to note that connection levels often overlap, and the same connector type may be used across multiple levels. Understanding this overlap helps clarify the functionality of various connectors.

3. Connector Classifications

Connectors are classified into three fundamental types based on their function and application: wire-to-wire, wire-to-board, and board-to-board connections.

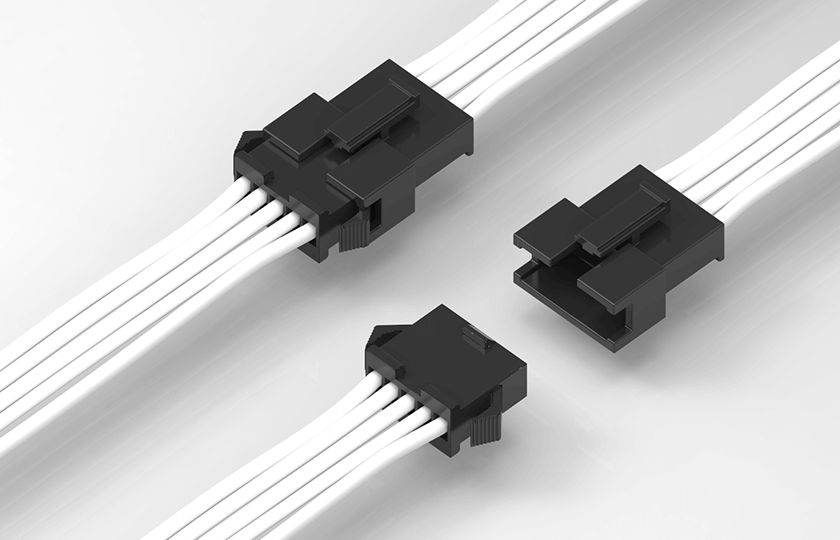

Wire-to-wire connectors include connections between individual wires or cables. Their defining characteristic is the permanent connection between corresponding wires. Common connection methods include:

-

- Crimping: Frequently used in discrete wire connectors for its simplicity and reliability.

- Insulation Displacement Connection (IDC): Ideal for multi-core cables, offering superior performance in wire-related and cable-end processing applications.

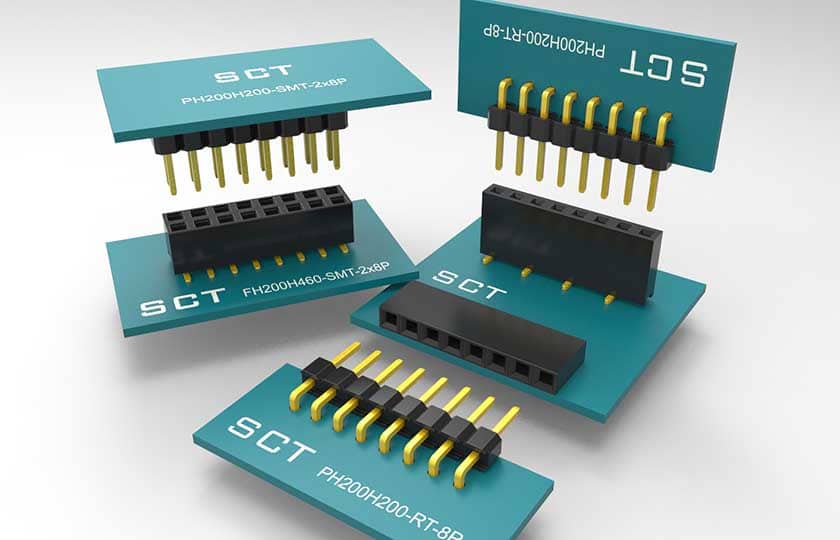

- Board-to-Board Connections

Board-to-board connectors come in two types: single-piece (card edge) and two-piece designs.- Single-piece connectors: Located at the edge of a circuit board and suited for simple connections.

- Two-piece connectors: Evolved due to the increasing complexity of printed circuit boards (PCBs). As board size and circuit density increase, the number of terminals rises, leading to higher insertion forces. Two-piece connectors meet these demands by distributing the load across multiple terminals.

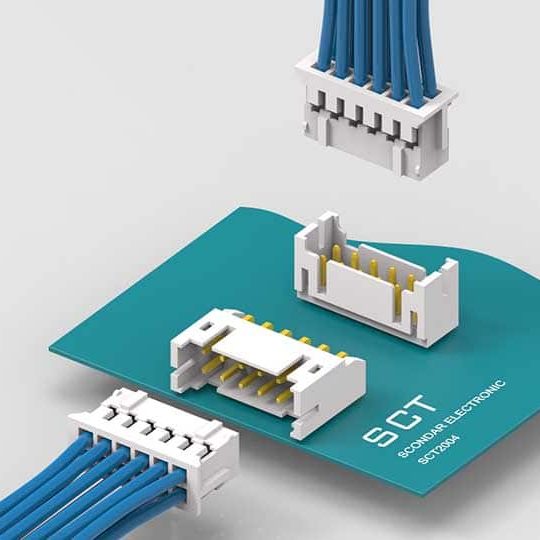

- Wire/Cable-to-Board Connections

This type connects a wire or cable on one end and a printed circuit board on the other.- Wire connections rely on crimping or IDC methods as described above.

- Board connections typically use press-fit or soldering techniques.

4. Functional Classification: Signal Transmission and Power Transmission

Electrical connectors are further categorized based on their primary function:

- Signal Transmission

Signal transmission connectors can handle either analog or digital signals.- Analog signals: Require connectors that maintain waveform and amplitude integrity.

- Digital signals: Operate at higher frequencies and require connectors that minimize signal degradation and preserve pulse shape. High-speed data signal connectors must address issues like characteristic impedance and crosstalk.

- In high-frequency applications, connectors are treated as transmission lines, where even minor variations in geometry can disrupt signal integrity. Controlling characteristic impedance and minimizing crosstalk are critical design objectives.

- Power Transmission

Power connectors are designed to handle higher currents compared to signal connectors.- Current capacity: Signal connectors typically handle currents under 1A, whereas power connectors manage tens or even hundreds of amperes.

- Joule heating: Power connectors generate significant heat due to high current flow, necessitating careful material selection and design to manage temperature rise.

5. Emerging Challenges and Trends

As connectors become smaller and denser, maintaining performance while adhering to durability and compatibility requirements poses significant challenges. For example:

- Miniaturized connectors must support thousands of mating cycles without performance degradation.

- High-speed signal connectors must meet stringent impedance and crosstalk requirements to support modern microelectronics.

- Power connectors must balance high current capacity with efficient thermal management.

These challenges drive innovation in materials, design techniques, and manufacturing processes to meet the evolving needs of electronic systems.

In conclusion, understanding the hierarchical levels, design considerations, and classifications of electrical connectors is essential for developing reliable and efficient interconnection systems. As technology advances, the demand for high-performance, durable, and standardized connectors will continue to grow, further shaping the future of connectivity solutions.